Батерийните клетки за кокошки носачкитрябва да осигури запазване на топлината и херметичност на кокошарниците, за да се постигне пълна автоматизация на отглеждането.

1. Сграда за пилета

ИзползвайтеСглобяеми стоманени конструкциии кокошарниците трябва да бъдат гъвкаво проектирани според мащаба на развъждане, а затворените кокошарници трябва да бъдат построени, за да се постигнат по-добре функциите на изолация/запазване на топлината.

2. Автоматична система за хранене

Включително кули за съхранение, спирални хранилки, хранилки, изравнители, корита за храна и оборудване за почистване на клетките. Кулата за храна и централната линия за хранене трябва да бъдат оборудвани със система за претегляне, за да отговарят на ежедневните автоматични нужди от хранене и изхранване на кокошарника. Капацитетът на кулата за храна трябва да отговаря на приема на храна на пилетата за 2 дни, а количеството храна трябва да се изчислява според мащаба на развъждане.

Захранващото устройство използва задвижваща система за подаване. На всеки слой на клетката трябва да има захранващ жлеб, а изпускателните отвори на всеки слой могат да изхвърлят материала едновременно, когато задвижването се движи по посока на устройството за подаване.

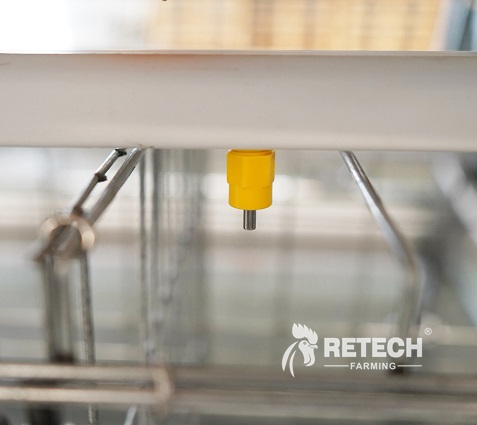

3. Автоматично оборудване за питейна вода

Автоматичната система за питейна вода включва тръби за питейна вода, нипели за питейна вода, дозиращи устройства, регулатори на налягането, редуцир-вентили, системи за обратна промивка и интелигентни системи за управление.

На входа за вода в кокошарника трябва да се монтират дозиращи устройства и филтри, за да се постигне филтриране на питейната вода и автоматично дозиране ѝ. В ранния етап на мътене и отглеждане всяко кокоше трябва да бъде оборудвано с регулируеми по височина тръбопроводи за питейна вода близо до горната мрежа на клетката и коритото за храна. Всяка клетка трябва да бъде оборудвана с 2-3 нипелни поилки, а под нипелните поилки трябва да се монтират чаши за вода;

В края на периода на отглеждане и снасяне на яйца, между средната преградна мрежа и горната мрежа трябва да се монтират тръбопроводи за питейна вода и V-образни поилки, за да се предотврати изтичането на питейна вода върху лентата за почистване на оборски тор. Тръбопроводите за питейна вода и другите материали трябва да бъдат изработени от устойчиви на корозия пластмаси. Регулатори на налягането на водата трябва да се монтират на всеки слой водопроводи, за да се осигури достатъчно водоснабдяване в предния и задния край на всеки слой водопроводи.

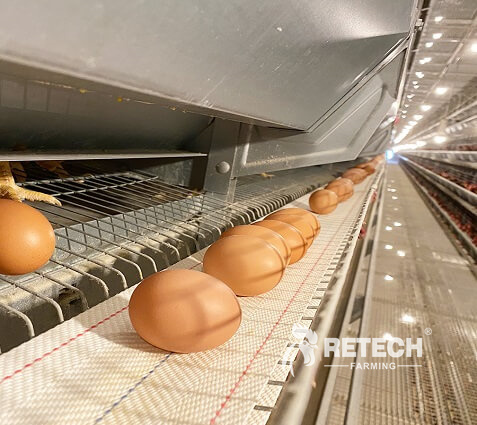

4. Автоматично оборудване за събиране на яйца

Включително ленти за събиране на яйца, машини за събиране на яйца, централни конвейерни линии за яйца, складове за яйца и машини за сортиране и опаковане на яйца.

По време на процеса на събиране на яйца, яйцата от всяка носачка трябва автоматично да се прехвърлят към горната решетка на клетката за пилета, след което яйцата трябва да се прехвърлят централно от кокошарника до склада за яйца за последващо опаковане през централната линия за събиране на яйца. По време на процеса на опаковане трябва да се използва машина за сортиране и опаковане на яйца за автоматично сортиране и подреждане на яйцата в тави. Ефективността на машината за сортиране и опаковане на яйца трябва да бъде конфигурирана според реалната производствена ситуация във фермата. Лентата за яйца трябва да бъде изработена от високоякостен нов полипропиленов материал PP5 или по-висок.

5. Автоматично оборудване за почистване на оборски тор

Трябва да се използва система за почистване на оборски тор от конвейерен тип, включваща надлъжни, напречни и наклонени конвейерни ленти за почистване на оборски тор, както и системи за захранване и управление (Фигура 5). Всеки слой от дъното на клетката трябва да бъде оборудван с конвейерна лента за послойно почистване, която се транспортира до задния край на кокошарника чрез надлъжна конвейерна лента. Изпражненията върху конвейерните ленти в долния край на всеки слой от клетката се остъргват от скрепера в задния край и попадат в долната напречна конвейерна лента, след което се транспортират извън сградата чрез напречни и наклонени конвейерни ленти, за да се гарантира, че „оборският тор не пада на земята“. Честотата на почистване на оборския тор трябва да се увеличи съответно. Препоръчително е оборският тор да се почиства ежедневно. Конвейерната лента за оборски тор трябва да е изработена от нов полипропиленов материал с антистатични, анти-стареещи и анти-отклоняващи функции. За да се предотврати контактът на пилетата с оборския тор върху конвейерната лента за оборски тор, над всеки слой клетки трябва да се монтира горна мрежа.

Автоматизиран контрол на околната среда

За триизмерно развъждане трябва да се използват напълно затворени кокошарници, а автоматичен контрол трябва да се постигне чрез оборудване за контрол на околната среда, като вентилатори в кокошарниците, мокри завеси, вентилационни прозорци и направляващи плочи.

1. Режим на контрол на околната среда при висока температура

През лятото трябва да се използва режим на вентилация и охлаждане с мокри завеси за всмукване на въздух и фронтонни вентилатори за отвеждане на въздуха. Високотемпературният въздух отвън се охлажда от мокрите завеси и след това се насочва от направляващите плочи в помещението за пилета, за да се гарантира, че температурата в помещението е в подходящ диапазон. Препоръчително е да се използва степенувано управление на мокрите завеси, за да се предотврати рязкото спадане на температурата в края на мократа завеса след отварянето ѝ.

2. Режим на контрол на околната среда в студен климат

Птичарникът използва режим на вентилация, който разчита на малък прозорец на страничната стена за всмукване на въздух и вентилатор на фронтона за отвеждане на въздуха. Минималната вентилация се извършва в зависимост от параметрите на околната среда, като концентрация на CO2 и температура вътре в птичарника, за да се гарантира качеството на въздуха в птичарника (контрол на концентрацията на CO2, прах, концентрация на NH3), като същевременно се намаляват загубите на топлина в птичарника и в крайна сметка се постига контрол на температурата в птичарника при студени климатични условия без отопление. Ъгълът на отваряне на мократа завеса и направляващата плоча на малкия прозорец за всмукване на въздух на страничната стена трябва да се регулират в зависимост от височината на клетката на птичарника и височината на тавана, за да се гарантира, че свежият въздух, влизащ в птичарника, навлиза в горното пространство на птичарника и образува струя, така че въздухът вътре и извън птичарника да може да постигне по-добър ефект на смесване и да се избегне директното вдухване на свежия въздух в клетката, причинявайки студен и топлинен стрес на пилетата.

3. Оборудване за автоматизирано управление

Трябва да се реализира напълно автоматизиран контрол на околната среда с интелигентен контролер за околната среда като ядро. Сензори за околната среда, като температура и влажност, скорост на вятъра, NH3, CO2 и др., трябва да бъдат разположени според размера на кокошарника и разпределението на клетките. Според интелигентния контролер за околната среда, параметрите на околната среда в кокошарника се анализират и отварянето и затварянето на оборудване за контрол на околната среда, като малки прозорци на страничните стени, направляващи плочи, вентилатори и мокри завеси, се контролира автоматично, за да се осъществи интелигентен контрол на средата в кокошарника. Регулира се еднородността и стабилността на средата за пилетата на различни места в кокошарника.

Цифрово управление

Триизмерното развъждане на кокошки носачки трябва да притежава характеристиките на интелигентност и информатизация, да осъществява дигитален контрол на пилешките ферми и да подобрява ефективността на управлението на развъждането.

Платформа за контрол на Интернет на нещата

Фермите за пилета трябва да изградят платформа за контрол на Интернет на нещата, за да осъществят взаимосвързването на данни от различни източници в кокошарника и да могат да предоставят ранно предупреждение в реално време за управление на многофамилни и многофамилни кокошарници, аномални явления при размножаване, да налагат планове за контрол на околната среда и да обобщават и анализират производствени данни. Дистанционното показване в реално време на условията на околната среда в кокошарника, състоянието на работата на кокошарника, нивото на здраве на кокошките и други данни може да помогне на мениджърите да вземат интелигентни решения.

Retech е надежден производител на оборудване за отглеждане на птици. Новата фабрика подобрява производствения капацитет и гарантира обем на доставките. Заповядайте на посещение!

Email:director@retechfarming.com

Време на публикуване: 03 юли 2024 г.